Grain d'acier pour préparation de surface robuste

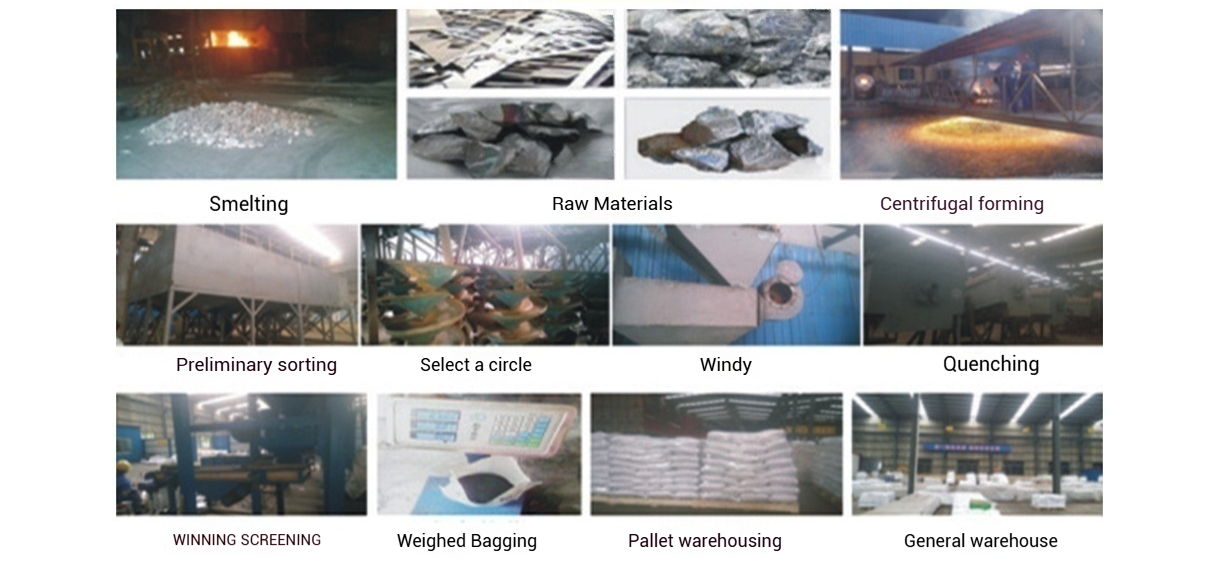

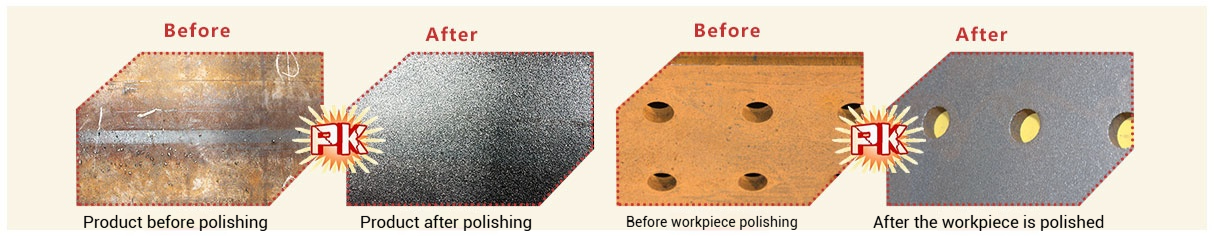

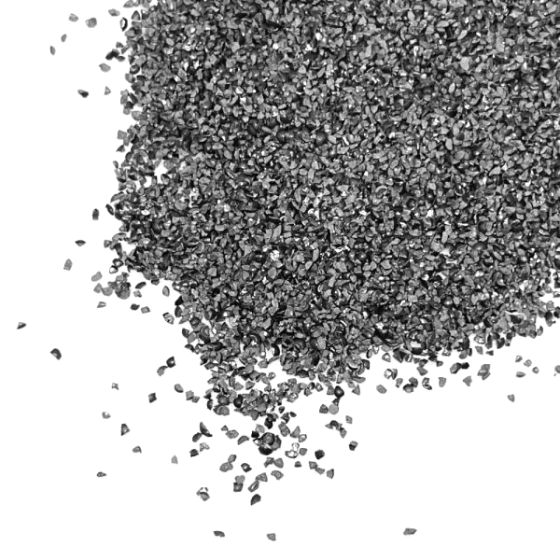

Manufacturers crush high-quality cast steel shot to produce Grain en acier abrasif. Contractors widely use this angular metallic blasting media in heavy-duty surface preparation such as descaling, déménagement, and surface roughening. Par conséquent, il offre une force d'impact agressive. Donc, il est idéal pour nettoyer les coques de navires, acier de construction, pipelines, et pièces moulées avant revêtement ou peinture. De plus, its sharp edges and high hardness ensure consistent performance across industries.

Principales caractéristiques du grain d'acier

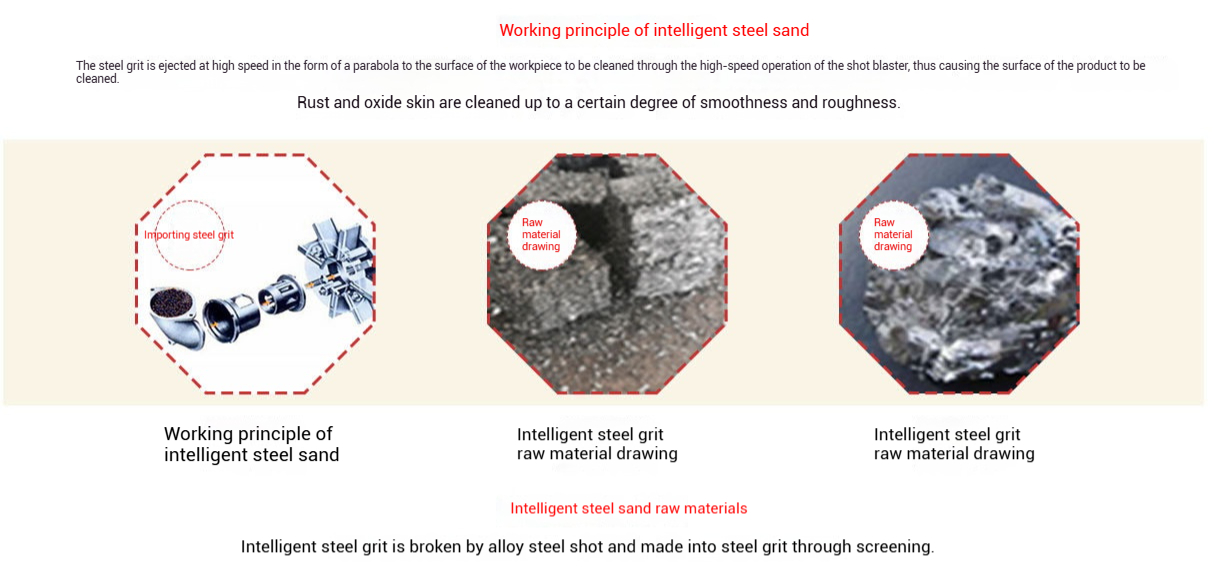

Forme angulaire pour un nettoyage agressif: Sharp-edged particles provide superior rust and scale removal. Donc, le dynamitage devient plus rapide et plus efficace.

High Hardness & Dureté: Offre un fort impact avec une excellente durabilité pour les cycles de dynamitage répétés. En outre, cela garantit une longue durée de vie dans les opérations de sablage industriel.

Long Reusability: Prend en charge plusieurs cycles de recirculation dans les systèmes de dynamitage en boucle fermée. De plus, cela réduit la consommation globale d'abrasif et les coûts du projet.

Profilage de surface efficace: Fournit une rugosité de surface constante qui améliore l’adhérence du revêtement. Par conséquent, les revêtements de protection durent plus longtemps et résistent aux environnements difficiles.

Large gamme de granulométries: Available in G10 to G120, ou personnalisé sur demande. Par conséquent, différentes industries peuvent sélectionner la taille qui correspond le mieux à leurs besoins en matière de dynamitage.

Spécifications techniques

| Apparence: | polygonal prism |

| Taille des particules (mm): | 0.3/0.5/0.7/1.0/1.2/1.5/1.7/2.0 |

Modèles de produits

| G10 | G12 | G14 | G16 | G18 | G25 |

| G40 | G50 | G80 | G100 | G120 |

Options d'emballage

We supply steel grit in:

25 Kg Sacs tissés en plastique, enveloppé de palettes à export (1000 kg / palette).

1000 KG Jumbo Bags (polypropylène tissé avec 4 boucles de levage).

En conclusion, les clients peuvent toujours sélectionner une méthode d'emballage adaptée à leurs besoins.

Applications industrielles des grains d'acier

Steel grit abrasive is applied in:

Construction et maintenance navales

Huile, Gaz, et installations pétrochimiques

Nettoyage de façades de monuments et de bâtiments

Projets d'infrastructure (Ponts, Tunnels)

Steel Fabrication and Construction Surface Preparation

👉 Pour les normes internationales de dynamitage, se référer à ISO 11126 – Préparation des substrats en acier.

👉 À la recherche de plus d'options? Visiter notre Aperçu des abrasifs de sable page.

FAQ

Q1: À quoi sert le grain d'acier?

Les entrepreneurs utilisent abrasif en acier pour le sablage pour enlever la rouille, échelle, et vieille peinture des structures en acier, pipelines, et coques de navires. Par conséquent, il améliore la propreté des surfaces et prolonge la durée de vie du revêtement.

Q2: Les grains d'acier peuvent-ils être réutilisés?

Oui. En fait, steel grit abrasive remains highly durable and contractors recycle it many times. Donc, it is a cost-effective choice for large blasting projects.

Q3: Quelle finition de surface les grains d'acier fournissent-ils?

Spécifiquement, steel grit abrasive produces an angular surface profile that improves coating adhesion. Par conséquent, coatings bond better and last longer in harsh conditions.