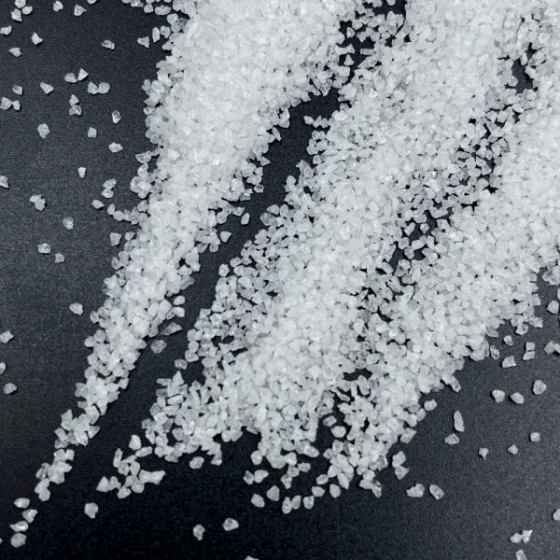

Alumina yang menyatu putih (WFA) Aplikasi – Etalase

Sorotan etalase ini Aplikasi Alumina Fused Putih dalam penggilingan presisi, pemolesan, dan produksi tahan api. Industri di seluruh dunia mengandalkan WFA karena kemurniannya yang tinggi, kekerasan, dan kemampuan memotong yang sangat baik. Lebih-lebih lagi, ia menawarkan kinerja yang stabil di lingkungan bersuhu tinggi dan presisi tinggi.

Keterangan

Produsen membuat White Fused Alumina dengan melebur alumina dalam tungku busur listrik. Hasilnya adalah bahan abrasif sintetis dengan lebih dari 99% kandungan Al₂O₃. Karena itu, itu memberikan kekerasan ekstrim (Mohs 9.0), stabilitas kimia, ketahanan termal, dan ujung tajam. Sebagai akibat, kontraktor dan produsen memilih WFA ketika mereka membutuhkan bahan abrasif yang andal.

Manfaat Utama Alumina Fused Putih

Komposisi bebas besi mencegah kontaminasi benda kerja.

Memberikan kinerja yang konsisten dalam penggilingan, pemolesan, dan peledakan pasir.

Menghasilkan debu minimal, meningkatkan keselamatan kerja.

Memenuhi standar FEPA dan ANSI untuk ukuran butiran abrasif.

Aplikasi Industri Alumina Fused Putih

Dirgantara dan elektronik menggunakan WFA untuk finishing dan lapping permukaan. Selain itu, fasilitas manufaktur metalurgi dan canggih mengandalkannya untuk persiapan yang presisi. Lebih-lebih lagi, produsen tahan api menerapkan WFA pada batu bata berbentuk, castable, dan bagian keramik. Keseluruhan, kemurnian dan kinerjanya menjadikannya penting bagi industri penting.

Keuntungan Tambahan

Aplikasi Alumina Fused Putih meluas ke produksi perangkat medis, komponen optik, dan keramik halus. Lebih-lebih lagi, ketajaman dan keamanannya membantu perusahaan mencapai efisiensi dan kualitas produk.

👉 Pelajari lebih lanjut di kami Halaman ikhtisar Sandblasting Abrasive.

👉 Referensi: FEPA – Federasi Produsen Abrasive Eropa.