Steel Grit – Applications & Vantaggi

Questa vetrina introduce Graniglia d'acciaio, a metallic abrasive valued for its hardness, riciclabilità, and aggressive cleaning action. Industries use this material for demanding surface preparation where strong cutting performance is needed. Inoltre, it creates stable anchor profiles that improve coating adhesion.

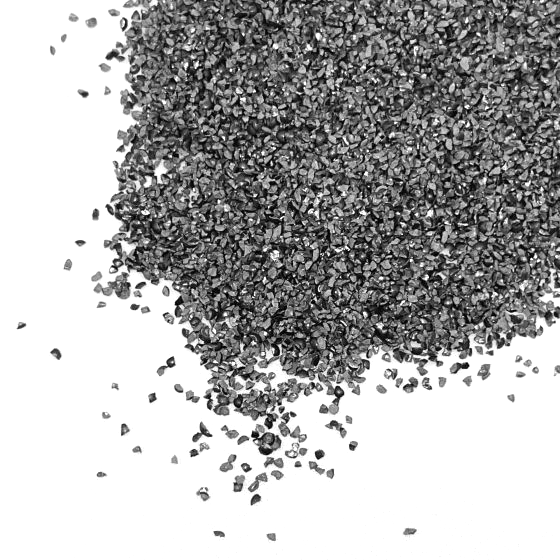

Descrizione

Steel grit is produced by crushing high-carbon steel shot, followed by screening and heat treatment. The process creates sharp-edged particles with high hardness. Perciò, this abrasive delivers strong impact force and consistent results. Di conseguenza, rimuove la ruggine, scala, and coatings quickly while ensuring reliable surface roughness.

Types of Steel Grit Applications

GP Grit: Rounded edges, ideal for general cleaning.

GL Grit: Medium angularity, used for both cleaning and profiling.

GH Grit: Highly angular, best for aggressive blasting and deep profiling.

Key Benefits of Steel Grit

Excellent cutting performance increases blasting speed.

Durable and recyclable, lowering overall abrasive consumption.

Versatility across multiple hardness grades.

Provides stable surface roughness. Inoltre, it ensures reliable coating adhesion.

Industrial Applications of Steel Grit

Shipyards apply this grit for hull cleaning. Inoltre, oil and gas projects use it to prepare pipelines and tanks. Construction and metalworking industries rely on it for descaling steel structures and machinery. Di conseguenza, coatings and welds achieve better bonding and long-term durability.

Extended Uses & Standard

Bridge renovation and rail transit projects also benefit from metallic blasting grit. Allo stesso modo, heavy equipment refurbishment depends on it for reliable results. Meanwhile, proper recycling and media classification help maintain blasting consistency. Complessivamente, compliance with Iso 11124 Standard sugli abrasivi metallici garantisce operazioni sicure ed efficienti.

👉 Esplora il nostro Pagina panoramica sugli abrasivi per sabbiatura.

👉 Riferimento: Iso 11124 – Standard sugli abrasivi metallici.