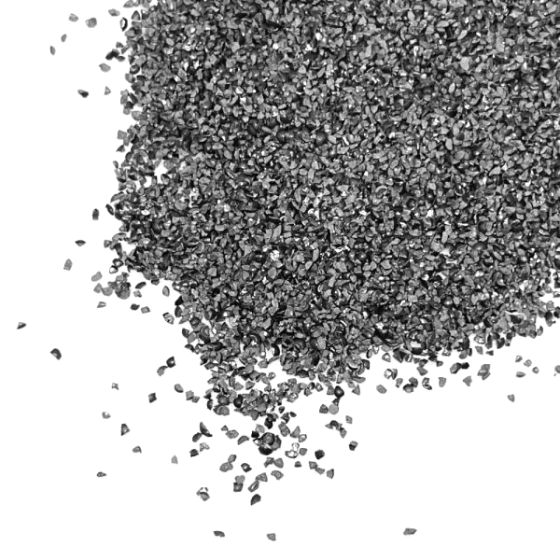

Black Fused Alumina Abrasive – High-Performance Blasting Media

Black Fused Alumina melelas, also known as black aluminum oxide, is a durable blasting material for rust removal and sandblasting. Manufacturers create it by smelting bauxite and iron oxide at high temperatures. Selain itu, its toughness, hardness, and reliable cutting performance make it suitable for large-scale projects. Akibatnya, industries such as shipyards, foundries, and fabricators rely on this abrasive for consistent results.

Key Features of Black Fused Alumina Abrasive

Moderate Hardness: Cuts effectively while reducing heat buildup. Akibatnya, operators achieve clean surfaces without damaging the base material.

Excellent Toughness: Resists fracturing under pressure. Di samping itu, this ensures stable performance across repeated blasting cycles.

Strong Impact Resistance: Handles aggressive cleaning and profiling. Oleh itu, it is ideal for ship hulls and steel fabrication.

Cost-Effective Operation: Provides high performance at competitive prices. Keseluruhan, its recyclability further lowers total project costs.

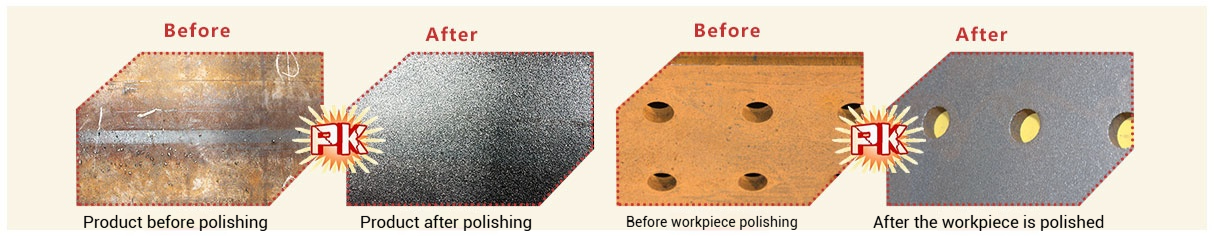

Optimized Surface Finish: Creates uniform anchor patterns. Contohnya, coatings on bridges and pipelines adhere better and last longer.

Spesifikasi Teknikal

| Penampilan: | Black, multi-angular granular powder |

| Particle Size Range: | F8–F220, customizable |

Available Grit Sizes

Popular mesh sizes include:20 mesh, 30 mesh, 46 mesh, 54 mesh, 60 mesh, 80 mesh, 100 mesh,120 mesh,150 mesh,170 mesh

| 20 mesh | 30 mesh | 46 mesh | 54 mesh | 60 mesh |

| 80 mesh | 100 mesh | 120 mesh | 150 mesh | 170 mesh |

👉 Learn more about ISO 8486 – Grain Size Distribution of Abrasives.

Packaging Options for Black Fused Alumina Abrasive

We supply BFA abrasive in:

25 kg plastic woven bags, menyusut dibungkus pada palet eksport (1000 kg per palet)

1000 kg jumbo bags with 4 mengangkat gelung

In conclusion, customers can also request custom packaging to match global logistics needs.

Industry Applications of black aluminum oxide abrasive

Black aluminum oxide abrasive is widely applied in:

Shipbuilding and Repair

Minyak, Gas, dan kemudahan petrokimia

Monument and Facade Restoration

Infrastructure Projects (Jambatan, Terowong)

Steel Structures and Industrial Surface Preparation

👉 Looking for more options? Lawati kami Sandblasting Abrasives overview page.

FAQ

Q1: What is Black Fused Alumina abrasive used for?

It is used for sandblasting, grinding, polishing, and surface cleaning. Akibatnya, industries rely on it for consistent and safe results.

Q2: Is Black Fused Alumina durable?

Ya. In fact, this abrasive resists fracturing and maintains toughness even in impact-intensive blasting.

Q3: Why choose Black Fused Alumina instead of Brown Fused Alumina?

Many industries prefer black aluminum oxide abrasive because it balances cutting efficiency with toughness. Contohnya, foundries and fabricators use it where durability and efficiency are equally important.