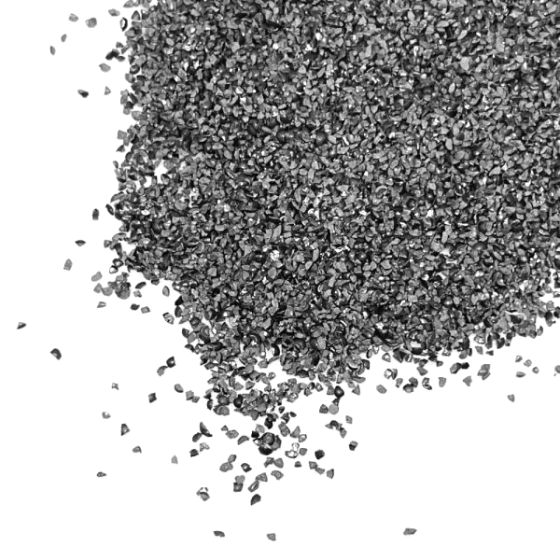

High Carbon Cut Wire Shot for Industrial Blasting

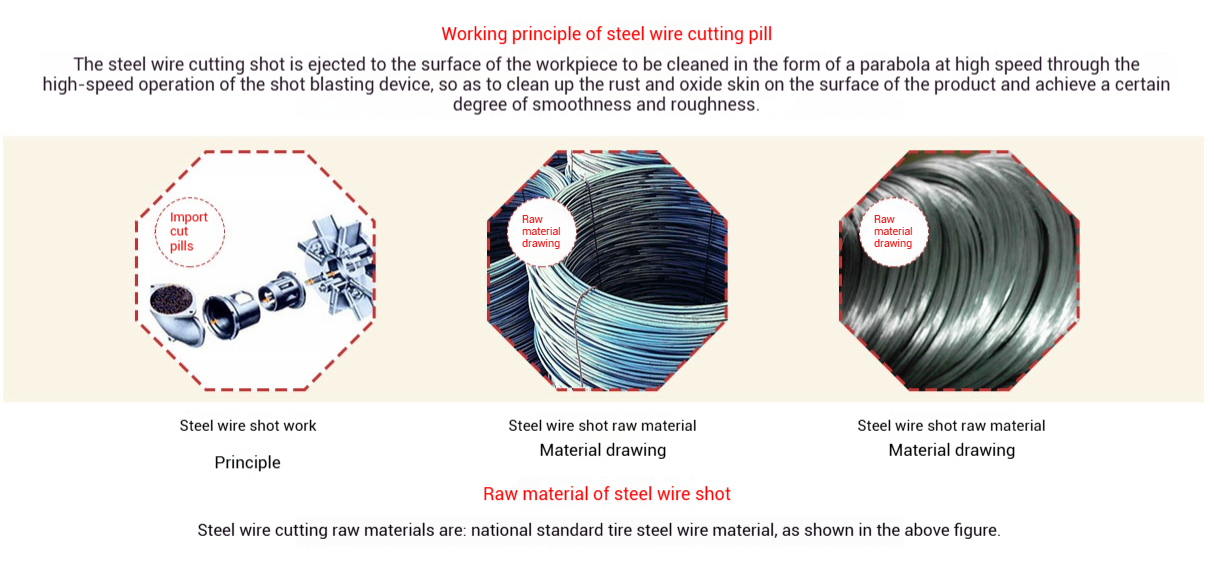

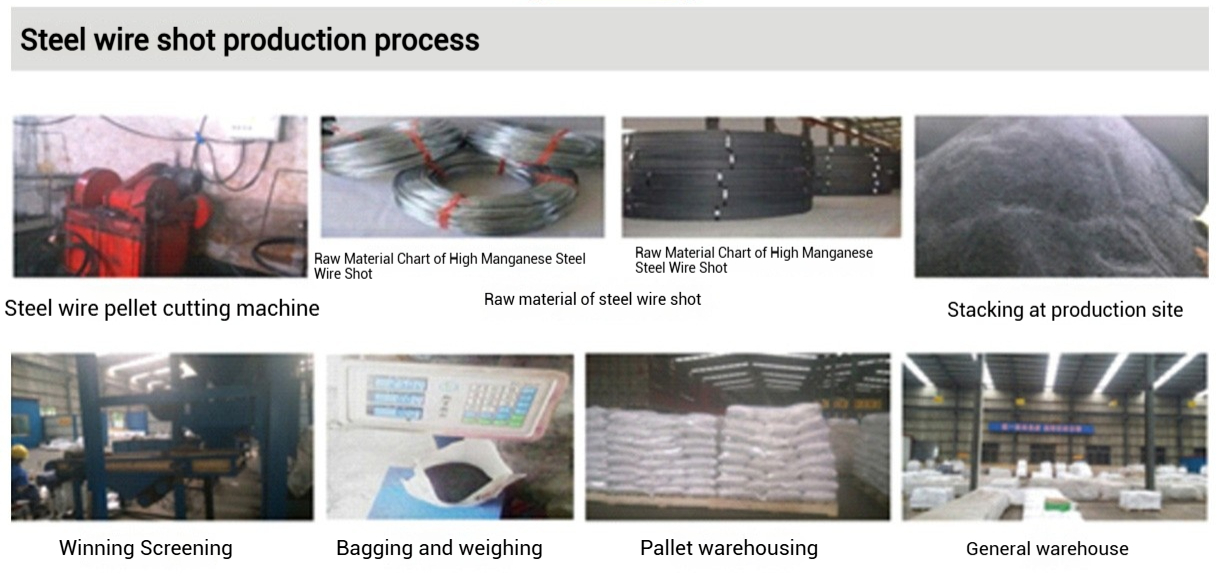

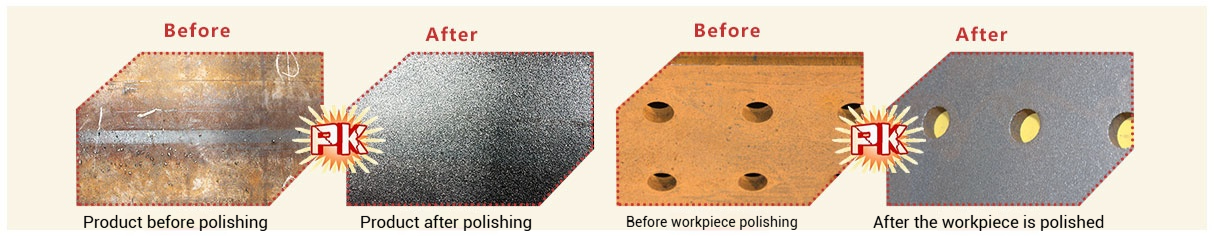

High Carbon Cut Wire Shot comes from cutting high-carbon steel wire into consistent cylindrical or conditioned round particles. Industries apply it in surface cleaning, penyingkiran karat, and shot peening of steel structures, ship hulls, and bridges. Selain itu, its toughness and hardness provide strong impact force. Akibatnya, operators achieve reliable blasting performance while extending coating life. Di samping itu, the uniform size ensures stable results across different blasting projects. Tambahan pula, its efficiency makes it a preferred choice for heavy-duty surface preparation.

Key Features of High Carbon Wire Shot

High Hardness & Strong Impact: This abrasive quickly removes rust and scale. Oleh itu, surfaces stay clean and ready for coating. Selain itu, operators save time during preparation.

Uniform Shape: Cylindrical or rounded particles provide stable blasting quality. Di samping itu, they minimize surface damage and improve consistency. Akibatnya, coatings adhere more effectively.

Low Breakage Rate: A dense structure resists fragmentation. Akibatnya, dust decreases, workplace safety improves, and visibility during blasting remains higher.

Durability & Reusability: Grains last through many blasting cycles. Akibatnya, users cut costs while keeping consistent performance. Tambahan pula, recycling supports sustainable operations.

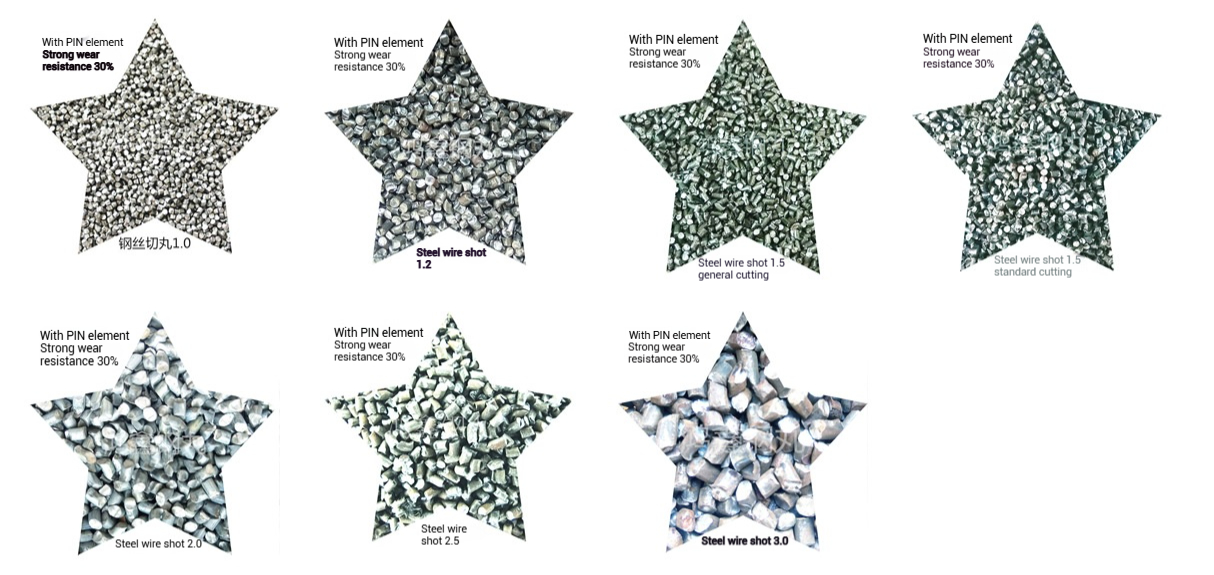

Flexible Sizes: Available in diameters from 0.5–3.5 mm. Contohnya, CW0.5 suits fine cleaning, while CW3.0 handles heavy-duty blasting. Di samping itu, custom sizes are available upon request.

Specifications

| Penampilan: | Cylindrical or conditioned round |

| Particle Sizes (mm): | 0.5/0.8/1.0/1.2/1.4/1.7/2.0/2.2/2.5/3.0/3.5 |

Product Models

| CW0.5mm | CW0.8mm | CW1.0mm | CW1.2mm | CW1.4mm | CW1.7mm |

| CW2.0mm | CW2.2mm | CW2.5mm | CW3.0mm | CW3.5mm |

Packaging Options for High Carbon Wire Shot

We supply High Carbon Cut Wire Shot abrasive in:

25 kg plastic woven bags, menyusut dibungkus pada palet eksport (1000 kg/pallet).

1000 kg jumbo bags with 4 mengangkat gelung.

In conclusion, flexible packaging supports both small and bulk orders. Selain itu, custom solutions are available for special projects.

Industry Applications of High Carbon Wire Shot

This blasting media is applied in:

Shot peening of automotive parts

Cleaning of railway wheels and axles

Hardening of springs, gears, and bearings

Foundry and casting surface preparation

Finishing of aerospace and heavy industrial equipment

👉 For shipyard or pipeline projects, explore our Halaman Produk Slag Tembaga Tembaga.

👉 Learn about ISO 26910 – Shot Peening Standards for international standards.

FAQ

Q1: What is this abrasive used for?

It is mainly applied for blasting, pembersihan, and peening of steel and alloy components. Tambahan pula, it supports a wide range of heavy-duty applications.

Q2: Can it be reused?

Ya. Its durability allows many blasting cycles. Akibatnya, this reduces abrasive consumption and lowers costs. Di samping itu, recycling improves environmental performance.

Q3: Why choose it over cast steel shot?

Because it provides lower breakage, stronger impact, and more uniform results. Oleh itu, users achieve higher efficiency and longer-lasting performance. Selain itu, consistent quality reduces rework.