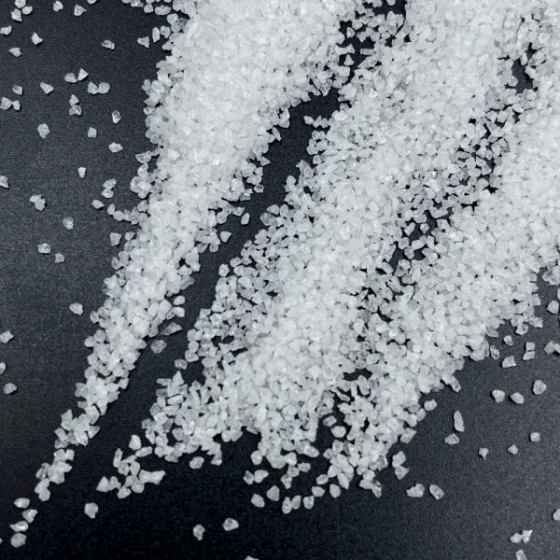

Alumina Bercantum Putih (WFA) Applications – Showcase

This showcase highlights White Fused Alumina Applications in precision grinding, polishing, and refractory production. Industries worldwide rely on WFA for its high purity, hardness, and excellent cutting ability. Selain itu, it offers stable performance in both high-temperature and high-precision environments.

Description

Manufacturers create White Fused Alumina by melting alumina in an electric arc furnace. The result is a synthetic abrasive with more than 99% Al₂O₃ content. Oleh itu, it delivers extreme hardness (Mohs 9.0), chemical stability, thermal resistance, and sharp cutting edges. Akibatnya, contractors and manufacturers choose WFA when they need reliable abrasives.

Key Benefits of White Fused Alumina

Iron-free composition prevents contamination of workpieces.

Delivers consistent performance in grinding, polishing, and sandblasting.

Produces minimal dust, improving workplace safety.

Meets FEPA and ANSI standards for abrasive grit sizes.

Industrial Applications of White Fused Alumina

Aerospace and electronics use WFA for surface finishing and lapping. Di samping itu, metallurgical and advanced manufacturing facilities rely on it for precision preparation. Tambahan pula, refractory producers apply WFA in shaped bricks, castables, and ceramic parts. Keseluruhan, its purity and performance make it essential for critical industries.

Additional Advantages

White Fused Alumina Applications extend to medical device production, optical components, and fine ceramics. Selain itu, its sharpness and safety help companies achieve both efficiency and product quality.

👉 Ketahui lebih lanjut mengenai kami Sandblasting Abrasives overview page.

👉 Reference: FEPA – Federation of European Producers of Abrasives.