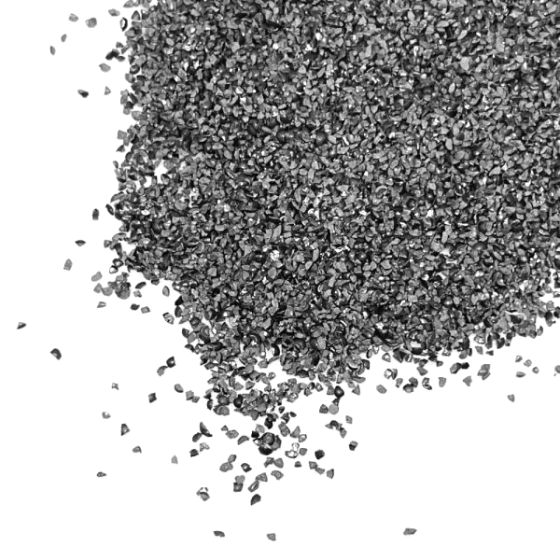

Zwart gesmolten aluminiumoxide schuurmiddel – Hoogwaardig straalmiddel

Zwart gesmolten aluminiumoxide schuurmiddel, ook bekend als zwart aluminiumoxide, is een duurzaam straalmateriaal voor ontroesten en zandstralen. Fabrikanten maken het door bauxiet en ijzeroxide bij hoge temperaturen te smelten. Bovendien, zijn taaiheid, hardheid, en betrouwbare snijprestaties maken het geschikt voor grootschalige projecten. Als resultaat, industrieën zoals scheepswerven, gieterijen, en fabrikanten vertrouwen op dit schuurmiddel voor consistente resultaten.

Belangrijkste kenmerken van zwart gesmolten aluminiumoxide schuurmiddel

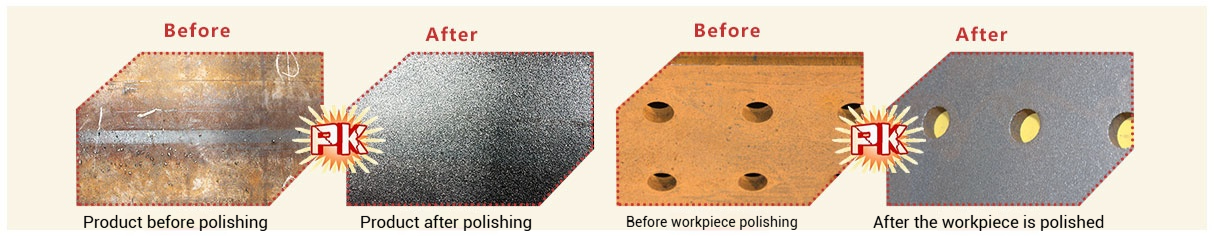

Matige hardheid: Snijdt effectief en vermindert de warmteontwikkeling. Vervolgens, operators bereiken schone oppervlakken zonder het basismateriaal te beschadigen.

Uitstekende taaiheid: Bestand tegen breuken onder druk. In aanvulling, dit zorgt voor stabiele prestaties tijdens herhaalde straalcycli.

Sterke slagvastheid: Geschikt voor agressieve reiniging en profilering. Daarom, het is ideaal voor scheepsrompen en staalproductie.

Kosteneffectieve werking: Biedt hoge prestaties tegen concurrerende prijzen. Algemeen, de recycleerbaarheid ervan verlaagt de totale projectkosten verder.

Geoptimaliseerde oppervlakteafwerking: Creëert uniforme ankerpatronen. Bijvoorbeeld, coatings op bruggen en pijpleidingen hechten beter en gaan langer mee.

Technische specificaties

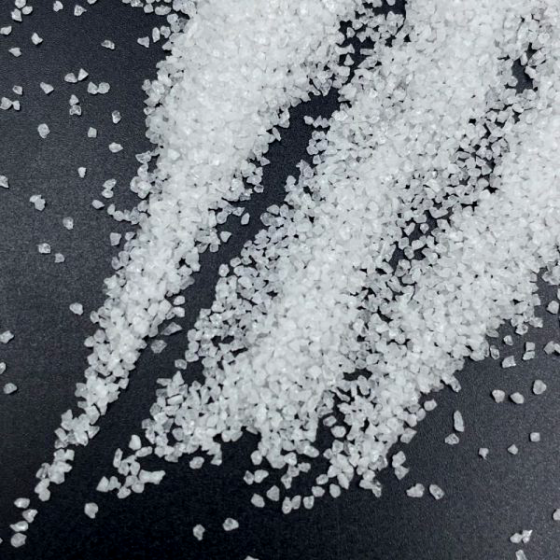

| Verschijning: | Zwart, meerhoekig korrelig poeder |

| Deeltjesgroottebereik: | F8–F220, aanpasbaar |

Beschikbare korrelgroottes

Populaire maaswijdten zijn onder meer:20 gaas, 30 gaas, 46 gaas, 54 gaas, 60 gaas, 80 gaas, 100 gaas,120 gaas,150 gaas,170 gaas

| 20 gaas | 30 gaas | 46 gaas | 54 gaas | 60 gaas |

| 80 gaas | 100 gaas | 120 gaas | 150 gaas | 170 gaas |

👉Meer informatie over ISO 8486 – Korrelgrootteverdeling van schuurmiddelen.

Verpakkingsopties voor zwart gesmolten aluminiumoxide schuurmiddel

Wij leveren BFA-schuurmiddel in:

25 kg plastic geweven zakken, in krimpfolie verpakt op exportpallets (1000 kg per pallet)

1000 kg jumbozakken met 4 hijslussen

Tot slot, klanten kunnen ook een aangepaste verpakking aanvragen om aan de wereldwijde logistieke behoeften te voldoen.

Industrie Toepassingen van zwart aluminiumoxide schuurmiddel

Zwart aluminiumoxide schuurmiddel wordt veel toegepast:

Scheepsbouw en reparatie

Olie, Gas, en petrochemische faciliteiten

Monumenten- en gevelrestauratie

Infrastructuurprojecten (Bruggen, Tunnels)

Staalconstructies en industriële oppervlaktevoorbereiding

👉Op zoek naar meer opties? Bezoek onze Overzichtspagina zandstraalmiddelen.

Veelgestelde vragen

Q1: Waar wordt Black Fused Alumina-schuurmiddel voor gebruikt??

Het wordt gebruikt voor zandstralen, slijpen, polijsten, en oppervlaktereiniging. Vervolgens, Industrieën vertrouwen erop voor consistente en veilige resultaten.

Vraag 2: Is zwart gesmolten aluminiumoxide duurzaam?

Ja. In werkelijkheid, dit schuurmiddel is bestand tegen breuken en behoudt zijn taaiheid, zelfs bij krachtig stralen.

Q3: Waarom kiezen voor Black Fused Alumina in plaats van Brown Fused Alumina?

Veel industrieën geven er de voorkeur aan zwart aluminiumoxide schuurmiddel omdat het snijefficiëntie en taaiheid in evenwicht brengt. Bijvoorbeeld, gieterijen en fabrikanten gebruiken het waar duurzaamheid en efficiëntie even belangrijk zijn.