Bruin gesmolten aluminiumoxide (BFA) – High-Performance Abrasive

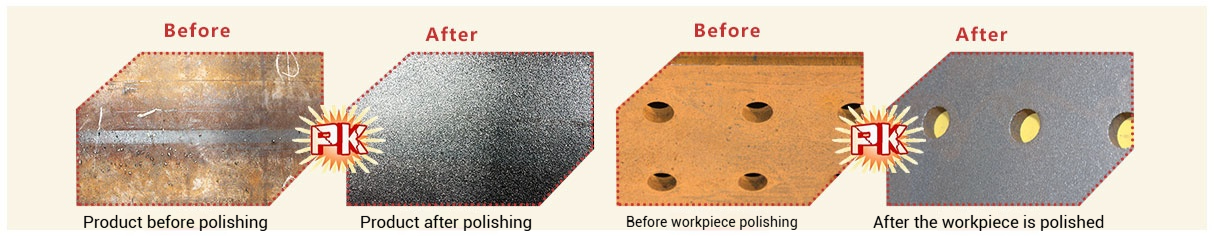

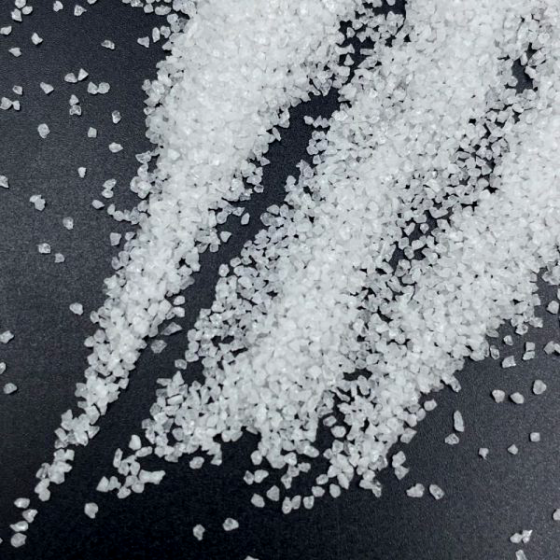

Brown Fused Alumina abrasive, ook bekend als brown aluminum oxide, is a high-hardness blasting media produced by the fusion of premium-grade bauxite in an electric arc furnace at over 2000°C. Bovendien, it offers outstanding toughness, abrasion resistance, and thermal conductivity. Als resultaat, it is widely applied in rust removal, sandblasting, bonded abrasives, and anti-slip flooring. In werkelijkheid, its aggressive cutting performance and durability make it a reliable choice for demanding industrial surface treatment tasks.

Key Advantages of Brown Fused Alumina

High Efficiency: Small particles accelerate airflow velocity, while angular grains deliver strong impact force. Vervolgens, blasting and grinding become faster and more effective.

Low Consumption: More efficient than garnet; it achieves results with less material. Daarom, projects save cost and reduce waste.

Low Dust Generation: High specific gravity minimizes airborne dust. Verder, it enhances workplace cleanliness and operator safety.

Technische specificaties

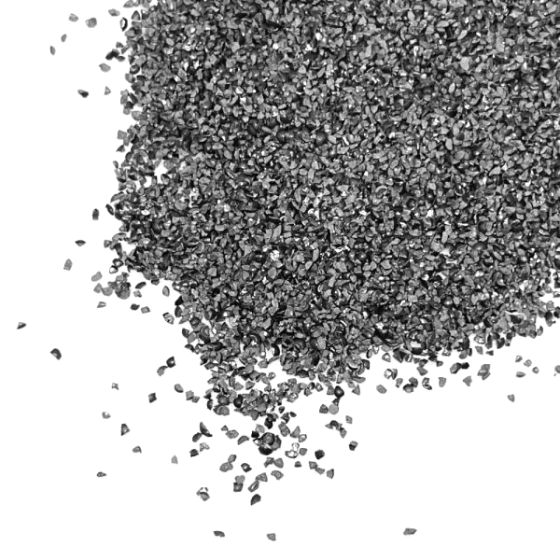

| Verschijning: | Brown, meerhoekig korrelig poeder |

| Deeltjesgroottebereik: | F4-F325 |

Beschikbare korrelgroottes

| 20 gaas | 36 gaas | 40 gaas | 46 gaas | 54 gaas | 60 gaas |

| 80 gaas | 100 gaas | 120 gaas | 150 gaas | 170 gaas |

👉 Learn more about global abrasive standards: ISO 8486 – Korrelgrootteverdeling van schuurmiddelen.

Verpakkingsopties

We supply BFA in:

25 kg plastic geweven zakken, in krimpfolie verpakt op exportpallets (1000 kg/pallet).

1000 kg jumbozakken (geweven polypropyleen met 4 hijslussen).

Custom packaging is available upon request.

Tot slot, customers can select the packaging method that best fits their project needs.

Industry Applications of Brown Fused Alumina

Brown Fused Alumina abrasive wordt toegepast:

Scheepsbouw en reparatie

Olie, Gas, en petrochemische faciliteiten

Monumenten- en gevelrestauratie

Infrastructuurprojecten (Bruggen, Tunnels)

Steel Structure and Construction Surface Preparation

👉 Op zoek naar meer opties? Bezoek onze Overzicht zandstraalmiddelen pagina.

Veelgestelde vragen

Q1: What is Brown Fused Alumina used for?

Industries use brown aluminum oxide for blasting, slijpen, polijsten, and refractory applications. Als resultaat, they benefit from its high hardness and toughness.

Vraag 2: Is BFA environmentally friendly?

Ja. In werkelijkheid, BFA abrasive contains no free silica and generates low dust during blasting operations. Daarom, operators enjoy safer workplace conditions.

Q3: What grit sizes are available for BFA?

Wij leveren alumina blasting media in grit sizes F12–F220. Bovendien, we also produce custom sizing upon request to meet project needs.