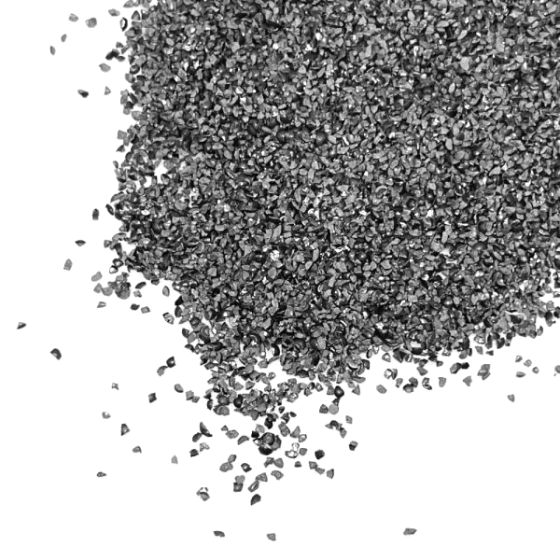

Product Overview – OEM Customized Abrasives

Our OEM-aangepaste schuurmiddelen are built for clients who require tailored blasting, polijsten, and finishing performance. Bovendien, we tune hardness, grit size, packaging, and branding to match exact project specs. Als resultaat, your team gains efficiency, consistent quality, and lower total cost.

Customization Options for OEM Customized Abrasives

We provide OEM flexibility across every stage. Specifiek, you can select:

Grit Sizes: From coarse 12 mesh to fine F240 and micron powders.

Material Types: Aluminum oxide, garnet, copper slag, stalen korrel, glass beads, and more.

Hardness Levels: Adjustable for substrate hardness and blasting pressure.

Branding: Private labeling, bag design, and logo printing.

Packaging: 25–30 kg bags, 1-ton jumbo bags, pallets, or bulk silos.

In aanvulling, we support special requests such as anti-slip floor abrasives and micro-powders for precision finishing.

Applications of OEM Customized Abrasives

Our solutions serve diverse scenarios. Bijvoorbeeld, shipyards and steel fabricators use them for rust removal and surface profiling. Verder, manufacturers rely on them for pre-coating roughening, precision cleaning, and deburring. Insgelijks, contractors apply custom blends to polish glass, ceramics, and stainless steel with stable results. Vervolgens, coatings adhere better and service life extends.

Case Example

An automotive client needed faster throughput without sacrificing finish. Daarom, we designed a blended grit that balanced cutting speed and surface smoothness. Afterwards, cycle time dropped, and rework rates fell. Algemeen, the OEM approach aligned performance targets with budget goals.

Why Choose Lianshun Abrasives

We back every project with process control and service. Additionally, our team brings 10+ years of manufacturing and export experience. Bovendien, we offer full QC testing, reliable global shipping, and responsive technical support.

Normen & Contact

Quality and safety matter in blasting. Accordingly, we align with ISO 11126 Mineral Abrasives for consistent performance. Finally, tell us your target profile, substrate, and machine type; we will propose a precise OEM recipe and sample plan.

👉 For more blasting options, bezoek onze Overzichtspagina zandstraalmiddelen.