Stainless Steel Shot Abrasive for Polishing and Peening

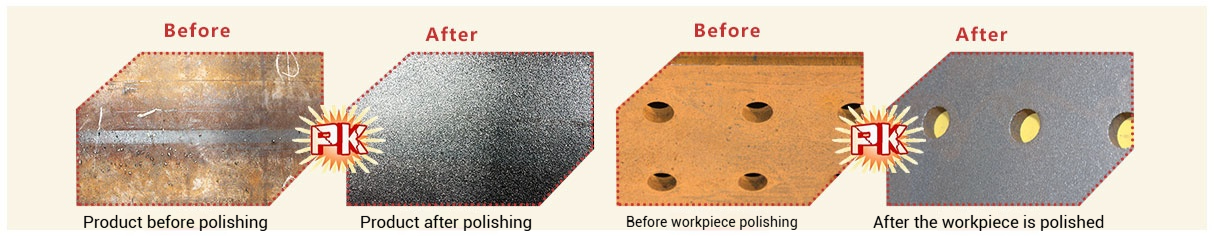

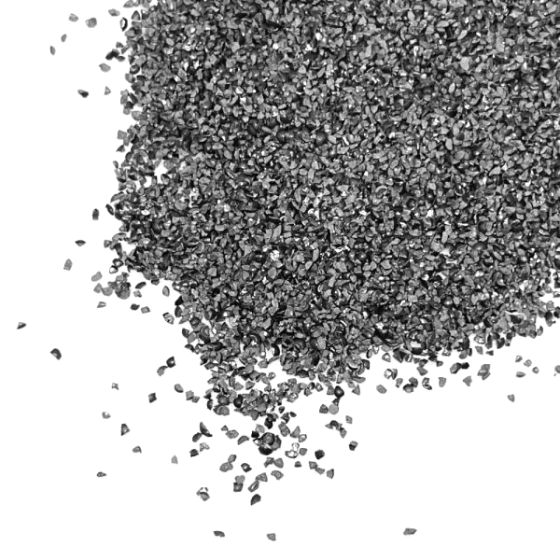

We manufacture Stainless Steel Shot Abrasive from high-quality stainless steel to ensure corrosion resistance and long service life. Bovendien, industries worldwide use this media for shot peening, cleaning, and polishing when iron-free results are mandatory. Als resultaat, it delivers a bright, smooth finish while limiting equipment wear. In werkelijkheid, thanks to excellent recyclability, stainless shot media performs exceptionally well in closed-loop systems. Algemeen, it offers the best balance between durability and performance.

Key Benefits of Stainless Steel Shot Abrasive

Rust-Free & Non-Contaminating:It prevents iron transfer on stainless and non-ferrous parts. Daarom, sensitive components keep their original color and cleanliness.

High Durability & Recyclability:Users recycle the media hundreds of times in closed systems. Vervolgens, total abrasive consumption and costs drop. In particular, large-scale projects gain major savings.

Smooth Surface Finish:It produces bright, low-roughness surfaces; in aanvulling, the finish suits hygienic and decorative requirements. Als resultaat, products maintain their shine for longer periods.

Weinig stof, Safer Operation:It generates minimal dust and no hazardous by-products. Verder, workplaces stay cleaner and visibility improves.

Multiple Sizes & Grades:Choose diameters 0.2#–3.0# and grades 410/430/304/201 to match your process. Insgelijks, custom specs are available on request, ensuring flexibility.

Productmodellen (Specifications)

| Sizes: | 0.2# | 0.3# | 0.4# | 0.5# | 0.6# | 0.8# | 1.0# | 1.2# |

| Sizes: | 1.5# | 1.8# | 2.0# | 2.5# | 3.0# | |||

| Grades: | 410 | 430 | 304 | 201 |

Packaging Options for Stainless Shot Media

We deliver stainless steel shot in:

25 kg plastic geweven zakken, in krimpfolie verpakt op exportpallets (1000 kg/pallet)

1000 kg jumbozakken met hijslussen

Custom packaging prepared upon request

In aanvulling, we prepare custom packaging upon request so logistics stay efficient. Als resultaat, clients in different regions get faster and safer deliveries.

Industry Applications of Roestvrij stalen schot

Industries apply stainless steel abrasive in:

Cleaning stainless steel and aluminum castings

Surface preparation of non-ferrous metals

Shot peening of automotive components

Finishing medical and food-grade equipment

Polishing decorative hardware and kitchenware

Treating precision parts that require rust-free results

👉 Learn more about international standards for peening at ISO 26910 – Shot peening.

👉 Op zoek naar meer opties? Bezoek onze Overzicht zandstraalmiddelen pagina.

Veelgestelde vragen

Q1: What is Stainless Steel Shot Abrasive used for?

It serves cleaning, polijsten, and shot peening of steel and non-ferrous parts. Daarom, teams achieve strong surfaces with low roughness.

Vraag 2: Is Stainless Steel Shot reusable?

Ja. Operators recycle the media for many cycles; as a result, projects reduce consumption and cost.

Q3: Where is Stainless Steel Shot commonly applied?

Industries use it in shipyards, automotive and aerospace plants, gieterijen, and medical equipment production. Verder, it ensures bright, rust-free finishes.