Staalgrit voor zware oppervlaktevoorbereiding

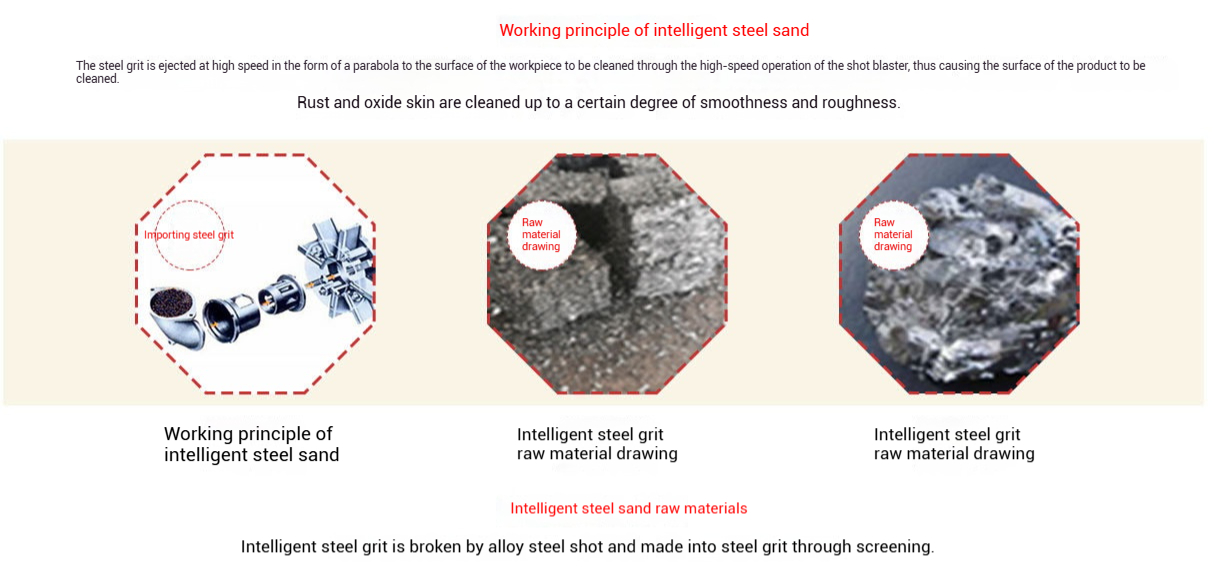

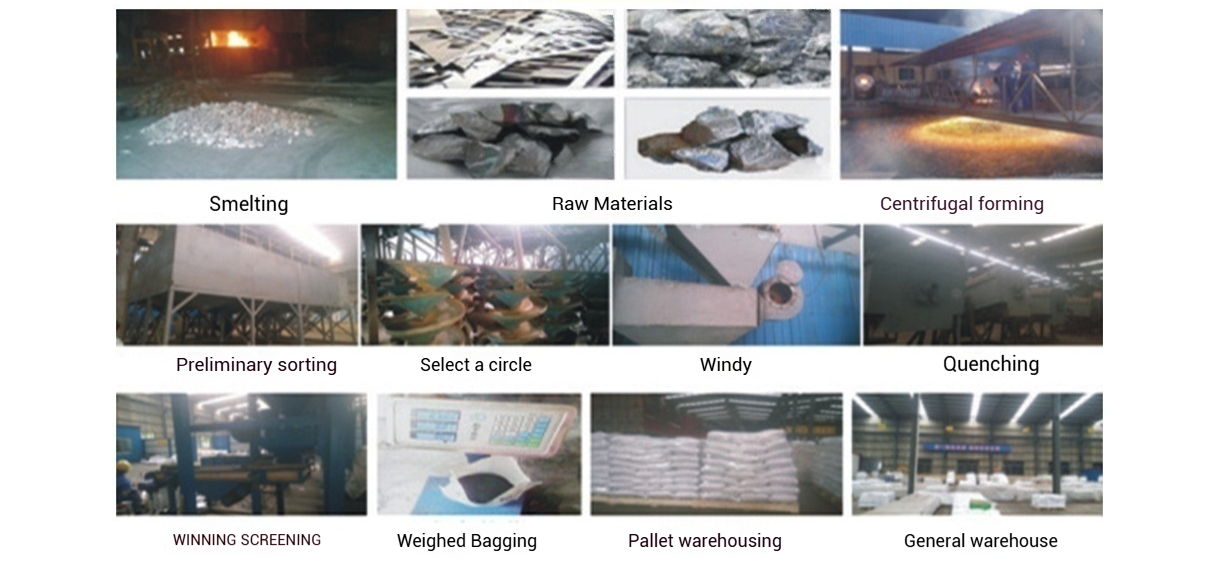

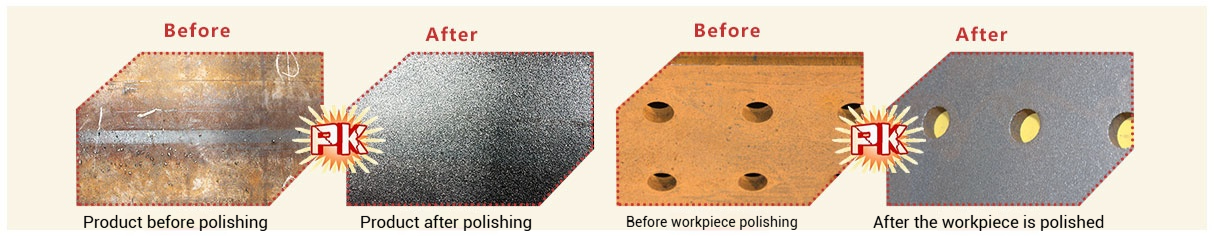

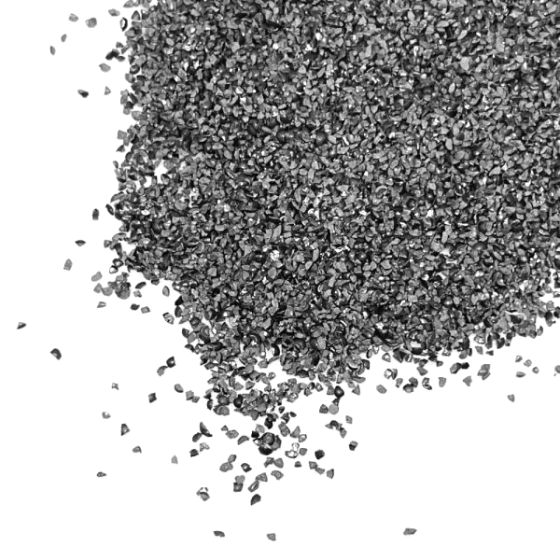

Fabrikanten verpletteren hoogwaardige gietstalen schoten om te produceren Schuurmiddel met staalkorrels. Aannemers gebruiken dit hoekige metalen straalmiddel op grote schaal bij zware oppervlaktevoorbereiding, zoals ontkalken, roest verwijderen, en oppervlakteruwheid. Als resultaat, het levert agressieve slagkracht. Daarom, het is ideaal voor het reinigen van scheepsrompen, constructiestaal, pijpleidingen, en gietstukken vóór het coaten of verven. Bovendien, de scherpe randen en hoge hardheid zorgen voor consistente prestaties in alle sectoren.

Belangrijkste kenmerken van staalgrit

Hoekige vorm voor agressieve reiniging: Scherpgerande deeltjes zorgen voor een superieure verwijdering van roest en aanslag. Daarom, stralen wordt sneller en efficiënter.

Hoge hardheid & Taaiheid: Biedt een sterke impact met uitstekende duurzaamheid voor herhaalde straalcycli. In aanvulling, dit garandeert een lange levensduur bij industriële straalwerkzaamheden.

Lange herbruikbaarheid: Ondersteunt meerdere recirculatiecycli in gesloten straalsystemen. Bovendien, dit vermindert het totale schuurmiddelverbruik en de projectkosten.

Efficiënte oppervlakteprofilering: Zorgt voor een consistente oppervlakteruwheid die de hechting van de coating verbetert. Vervolgens, beschermende coatings gaan langer mee en zijn bestand tegen zware omstandigheden.

Breed korrelgroottebereik: Verkrijgbaar in G10 tot G120, of op aanvraag aangepast. Als resultaat, verschillende industrieën kunnen het formaat selecteren dat het beste bij hun straalvereisten past.

Technische specificaties

| Verschijning: | veelhoekig prisma |

| Deeltjesgrootte (mm): | 0.3/0.5/0.7/1.0/1.2/1.5/1.7/2.0 |

Productmodellen

| G10 | G12 | G14 | G16 | G18 | G25 |

| G40 | G50 | G80 | G100 | G120 |

Verpakkingsopties

Wij leveren staalgrit in:

25 kg plastic geweven zakken, in krimpfolie verpakt op exportpallets (1000 kg/pallet).

1000 kg jumbozakken (geweven polypropyleen met 4 hijslussen).

Tot slot, klanten kunnen altijd een verpakkingsmethode kiezen die bij hun behoeften past.

Industrietoepassingen van staalgrit

Schuurmiddel met staalkorrel wordt toegepast:

Scheepsbouw en Onderhoud

Olie, Gas, en petrochemische faciliteiten

Gevelreiniging van monumenten en gebouwen

Infrastructuurprojecten (Bruggen, Tunnels)

Staalfabricage en voorbereiding van constructieoppervlakken

👉 Voor internationale straalnormen, verwijzen naar ISO 11126 – Voorbereiding van staalsubstraten.

👉 Op zoek naar meer opties? Bezoek onze Overzicht zandstraalmiddelen pagina.

Veelgestelde vragen

Q1: Waar wordt staalgrit voor gebruikt??

Aannemers gebruiken schuurmiddel met staalkorrels voor het stralen om roest te verwijderen, schaal, en oude verf van staalconstructies, pijpleidingen, en scheepsrompen. Als resultaat, het verbetert de oppervlaktereinheid en verlengt de levensduur van de coating.

Vraag 2: Kan staalgrit hergebruikt worden??

Ja. In werkelijkheid, Schuurmiddel met staalkorrels blijft zeer duurzaam en aannemers recyclen het vele malen. Daarom, het is een kosteneffectieve keuze voor grote straalprojecten.

Q3: Welke oppervlakteafwerking biedt staalkorrel??

Specifiek, staalkorrelschuurmiddel produceert een hoekig oppervlakteprofiel dat de hechting van de coating verbetert. Vervolgens, coatings hechten beter en gaan langer mee onder zware omstandigheden.