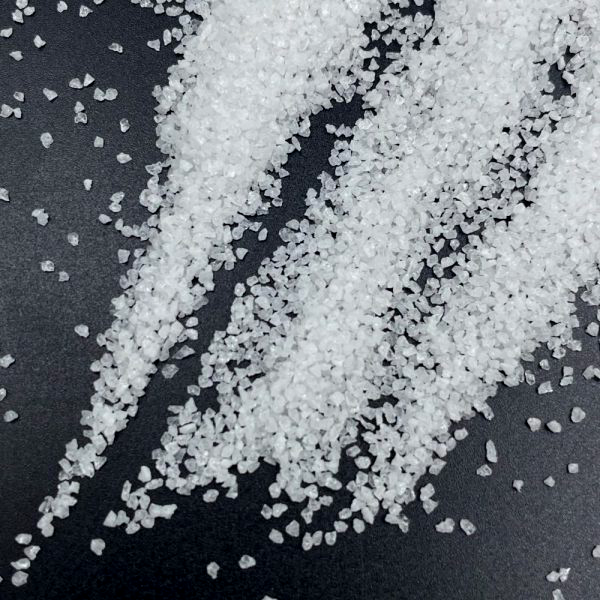

Product Overview – White Fused Alumina

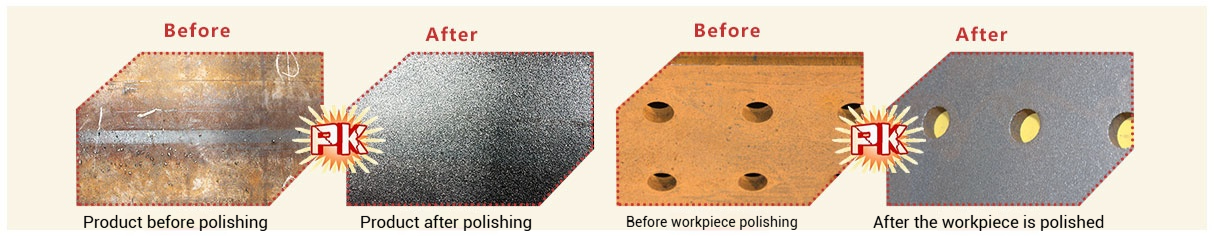

Wit gesmolten aluminiumoxide (WFA) is a high-purity synthetic abrasive made by fusing industrial-grade alumina in an electric arc furnace. Bovendien, it combines exceptional hardness, sharp cutting edges, and strong chemical stability. Als resultaat, manufacturers choose WFA for precision blasting, oppervlakteafwerking, and polishing of stainless steel, aluminum, ceramics, glass, and electronic components. In werkelijkheid, its iron-free composition ensures contamination-free results, making it ideal for high-end industries.

Key Features of White Fused Alumina

High Purity & Cutting Ability: WFA delivers precise micro-deburring and fine polishing.

Non-Contaminating Results: It contains no iron, so users avoid stains or surface defects.

Versatile in Wet & Dry Blasting: Verder, it performs reliably in both wet and dry applications.

Thermal & Chemical Stability: It resists heat and chemicals, ensuring long-term stability.

Low Friability: Vervolgens, grains last longer, and operators reuse them many times.

Technische specificaties

| Verschijning: | White, meerhoekig korrelig poeder |

| Deeltjesgrootte: | Granules or powder, F8–F220 range |

Beschikbare korrelgroottes

Common mesh sizes include: 20 gaas, 36 gaas, 46 gaas, 60 gaas, 80 gaas, 120 gaas, 150 gaas(Custom sizes available upon request)

| 20 gaas | 36 gaas | 46 gaas | 60 gaas |

| 80 gaas | 120 gaas | 150 gaas |

Verpakkingsopties

25 kg plastic geweven zakken, shrink-wrapped on pallets (1000 kg/pallet)

1000 kg jumbozakken met hijslussen

Custom packaging available on request

Industry Applications of White Fused Alumina

Manufacturers use WFA in:

Electronic component cleaning

Stainless steel and aluminum finishing

Medical and dental instrument polishing

Glass and ceramic frosting

Sandblasting of 3C product housings (phones, laptops)

In aanvulling, aerospace and energy industries also use WFA for contamination-free surface treatment. Daarom, it remains a trusted abrasive in advanced sectors.

Why Choose White Fused Alumina from Lianshun

We supply White Fused Alumina with strict QC and global shipping. Additionally, our team has more than 10 years of manufacturing and export experience. Bovendien, we ensure compliance with ISO 11126 Mineral Abrasives for reliable results.

👉 Visit our Overzichtspagina zandstraalmiddelen for more options.

Veelgestelde vragen

Q1: What is White Fused Alumina used for?

Manufacturers use it for blasting, polijsten, and finishing metals, ceramics, and electronics.

Vraag 2: Can WFA be reused?

Ja. Als resultaat, operators recycle its grains many times, cutting costs.

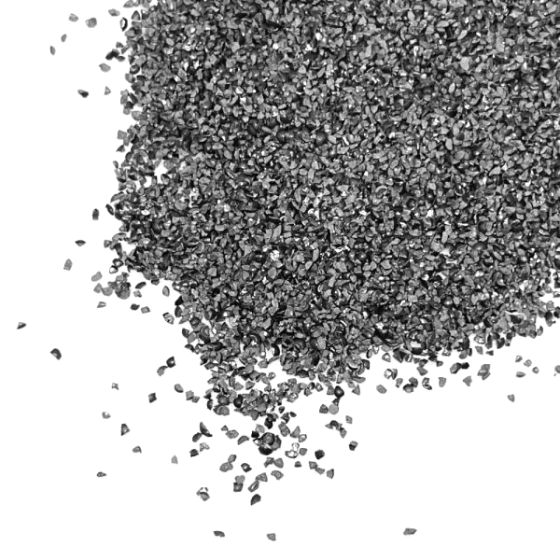

Q3: Why choose WFA instead of Brown Fused Alumina?

WFA offers higher purity and avoids contamination. Daarom, it is better for sensitive applications.