Opis:

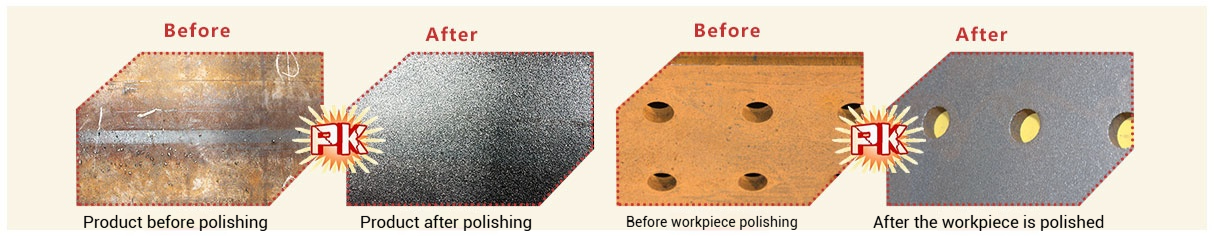

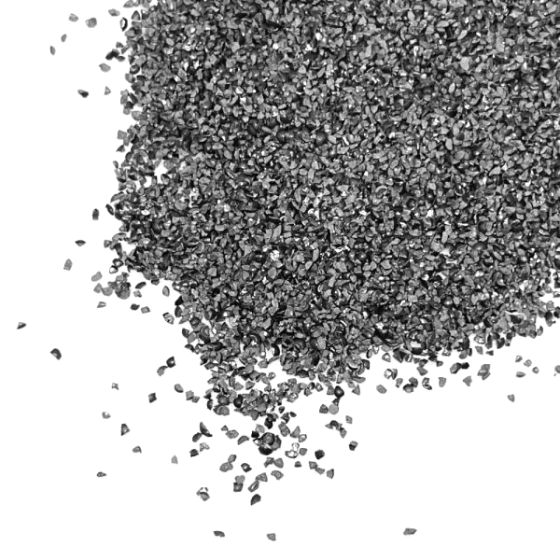

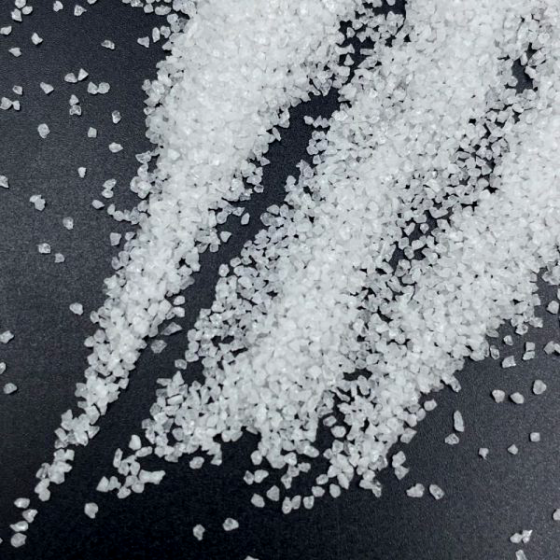

High manganese cut wire shot is manufactured by cutting high-manganese alloy steel wire into uniform cylindrical or conditioned round shapes. It is widely used for surface cleaning, descaling, shot peening, and rust removal on components that require high impact resistance and extended fatigue life, such as automotive parts, aerospace components, railway wheels, and steel structures.

Kluczowe funkcje:

High Impact Resistance:Ideal for applications demanding high fatigue strength and enhanced surface hardening.

Low Dust & Uniform Shape:Consistent cylindrical or rounded shape ensures stable blasting performance and reduced dust generation.

Excellent Recyclability:Durable and wear-resistant, enabling multiple reuse cycles in closed-loop blasting systems.

- Custom Sizes Available:Available from 0.5 mm to 3.5 mm to suit various equipment types and process needs.

We offer a wide range of particle sizes to meet different sandblasting and surface treatment requirements.

Product Model (Specification):

| CW0.5mm | CW0.8mm | CW1.0mm | CW1.2mm | CW1.4mm | CW1.7mm |

| CW2.0mm | CW2.2mm | CW2.5mm | CW3.0mm | CW3.5mm |

Opcje pakowania:

- 30 kg plastikowe tkane torby, zawinięte w palet eksportowych (całkowity 1050 kg/pallet).

- 1000 KG Jumbo torebki (tkany polipropylen z 4 Pętle podnoszące).

- Custom packaging available upon request.

Aplikacje branżowe:

- Shot peening of automotive components

- Surface cleaning of railway wheels and axles

- Finishing of aerospace and aviation parts

- Cleaning of precision engine components

- Surface preparation of steel structures and castings

- Shot peening of springs, gears, and bearings

Skontaktuj się z nami for customized solutions, Pełne techniczne arkusze danych, or a free sample quotation.