Alloy Steel Shot Abrasive – Durable Media for Blasting

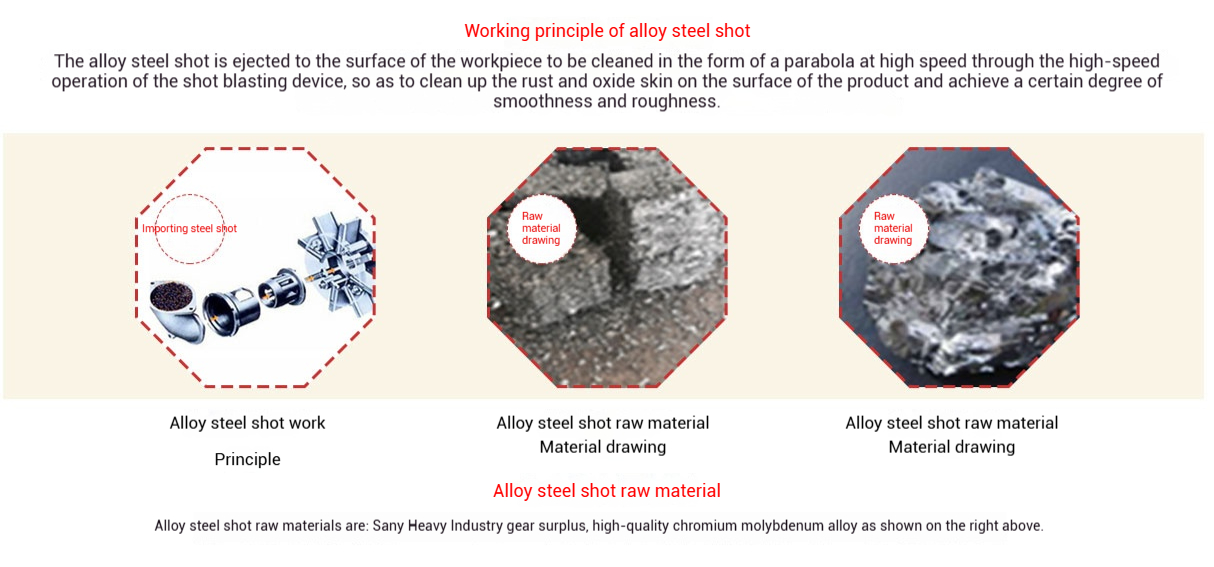

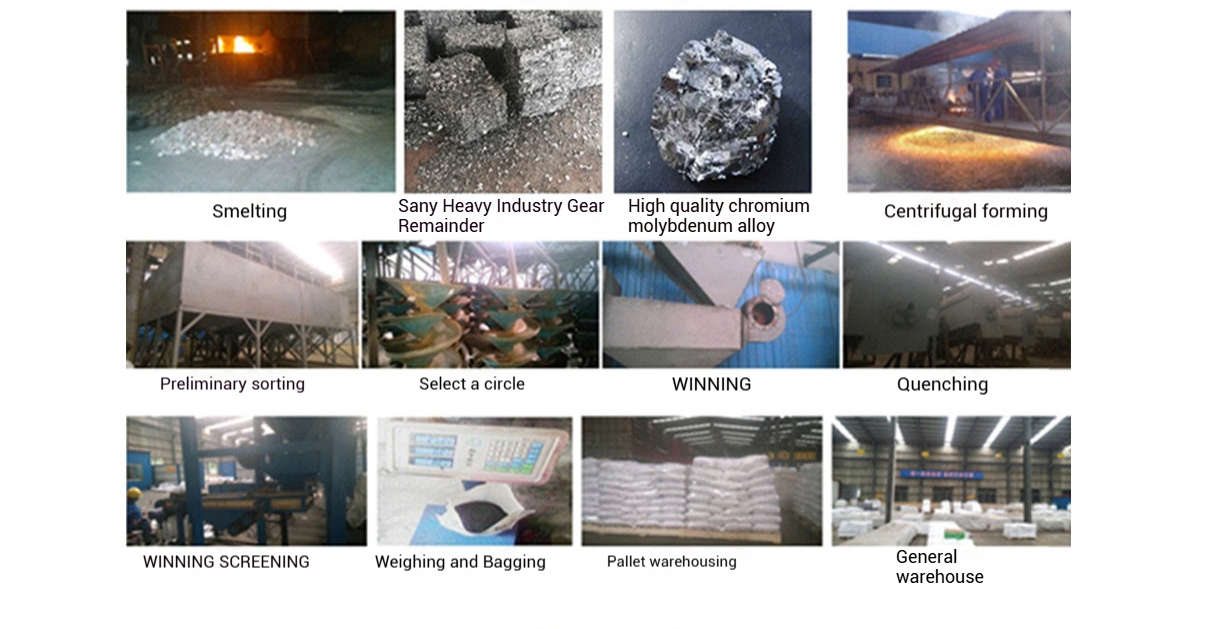

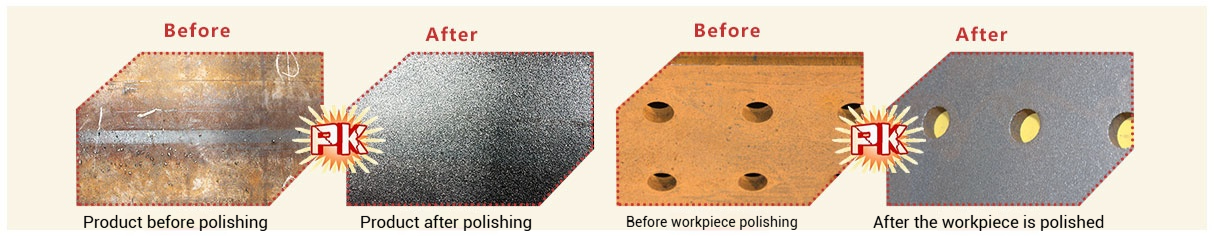

Alloy steel shot abrasive comes from premium alloy cast steel processed with strict heat treatment. Industries rely on it for descaling, Pag -alis ng kalawang, and shot peening of structural steel, castings, Mga barko ng barko, and railway vehicles. Bukod dito, its dense microstructure and consistent hardness deliver uniform blasting performance. Bilang isang resulta, operators gain excellent rebound efficiency and extend service life. Bilang karagdagan, alloy steel shot performs reliably in turbine blasting machines and closed-loop systems.

Key Features of Alloy Steel Shot

High Rebound Performance: Alloy steel shot boosts cleaning efficiency. Samakatuwid, coverage improves in turbine blasting equipment.

Balanced Hardness and Toughness: It delivers strong impact while reducing abrasive wear. Bukod dito, the substrate remains protected.

Excellent Durability: Users recycle the grains for more than 2,000 blasting cycles. Dahil dito, costs remain lower and efficiency increases.

Uniform Particle Size: Consistent results guarantee even surface finishes. Bilang karagdagan, blasting quality stays stable over time.

Meets International Standards: The product follows ISO 9000:1998. Bukod dito, it complies with SAE specifications.

Teknikal na Pagtutukoy

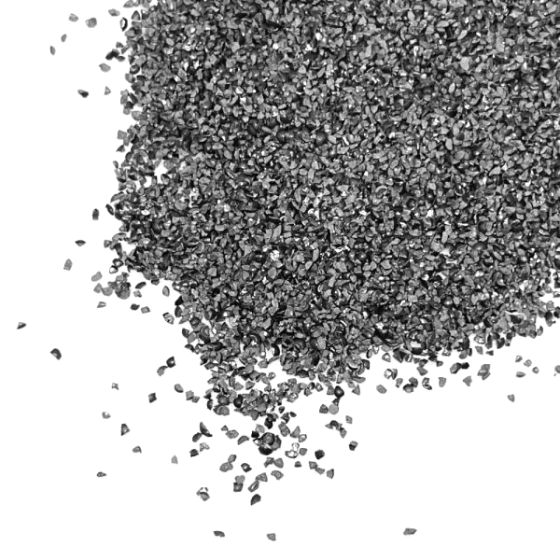

| Hitsura: | Spherical or near-spherical |

| Available Sizes (mm): | 0.2/0.3/0.4/0.5/0.6/0.8/1.0/1.2/1.4/1.7/2.0/2.5/3.0 |

Mga modelo ng produkto (SAE Specs)

| S70 | S110 | S130 | S170 | S230 | S280 | S330 |

| S390 | S460 | S550 | S660 | S780 | S930 |

Mga Pagpipilian sa Pag-iimpake

We provide alloy steel shot in:

25 kg woven bags, Ang pag-urong ay nakabalot sa mga palyete ng pag-export (1000 kg/papag).

1000 kg jumbo bags with lifting loops.

Additionally, custom packaging supports special project needs.

Industry Applications of Alloy Steel Shot Abrasive

Alloy steel shot abrasive is widely applied in:

Shipbuilding and vessel maintenance

Langis, gas, and petrochemical facilities

Bridge and tunnel infrastructure projects

Monument and facade cleaning

Steel structure and construction blasting

👉 For alternative solutions, see our Copper slag nakasasakit or Steel Grit products.

👉 Learn more about international shot peening standards at ISO 26910.

FAQ

Q1: What is alloy steel shot abrasive used for?

Industries use it for cleaning, descaling, and peening of steel structures, castings, and large fabricated components.

Q2: Can alloy steel shot be reused?

Oo. Operators recycle alloy steel shot thousands of times. Samakatuwid, abrasive consumption decreases and project costs fall.

Q3: Why choose alloy steel shot instead of carbon steel shot?

Because alloy steel shot offers stronger durability. Bukod dito, it provides more stable performance and reduces operational costs.