High Manganese Cut Wire Shot Abrasive – Durable Peening Media

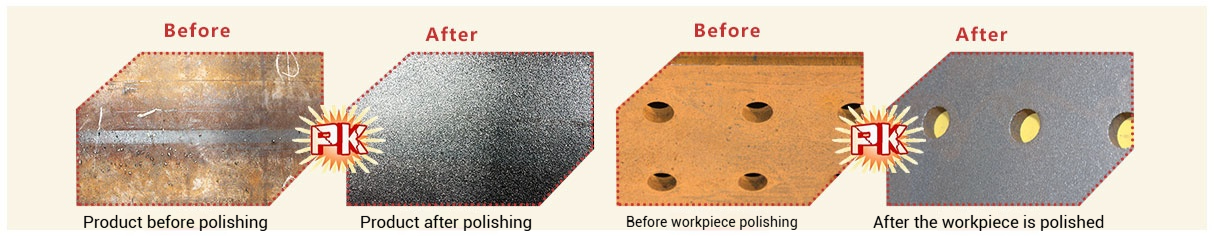

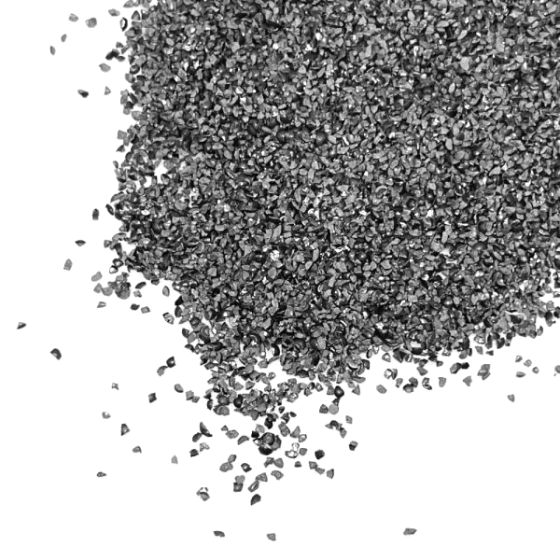

High Manganese Cut Wire Shot abrasive comes from alloy steel wire cut into round or cylindrical particles. Industries use this metallic blasting media for shot peening, descaling, Pag -alis ng kalawang, and precision cleaning. Bukod dito, its toughness ensures strong impact resistance. Bilang isang resulta, it extends the fatigue life of automotive, aerospace, and railway components. Bilang karagdagan, the uniform particle size guarantees consistent performance. Sa pangkalahatan, this abrasive offers both reliability and cost-efficiency.

Key Features of High Manganese Abrasive

High Impact Resistance: This abrasive resists repeated stress. Dahil dito, it strengthens fatigue resistance and improves durability.

Low Dust & Pantay na hugis: The media provides stable blasting results. Bukod dito, it minimizes airborne dust and promotes operator safety.

Excellent Recyclability: Users recycle this abrasive multiple times. Samakatuwid, it reduces material usage and lowers project costs.

Custom Sizes Available: Sizes range from 0.5 mm to 3.5 mm. Halimbawa, contractors select the most suitable size for their blasting machines.

Product Model (Specification)

| CW0.5mm | CW0.8mm | CW1.0mm | CW1.2mm | CW1.4mm | CW1.7mm |

| CW2.0mm | CW2.2mm | CW2.5mm | CW3.0mm | CW3.5mm |

Packaging Options for High Manganese Cut Wire Shot

Kami ay nagsusuplay high manganese cut wire blasting media in:

25 kg plastic na pinagtagpi mga bag, Ang pag-urong ay nakabalot sa mga palyete ng pag-export (1000 kg/papag)

1000 kg jumbo bag na may 4 nakakataas na mga loop

Sa konklusyon, custom packaging is also available to suit international project needs.

Industry Applications of High Manganese Cut Wire Shot Abrasive

High manganese abrasive is widely used in:

Shot peening of automotive components.

Paglilinis ng mga gulong ng tren at axle.

Finishing of aerospace and aviation parts.

Maintenance of precision engine components.

Surface preparation of castings and steel structures.

Peening of gears, bearings, and springs.

👉 Learn more about ISO 26910 - Mga Pamantayan sa Peening Peening.

👉 Looking for alternatives? See our Pangkalahatang-ideya ng Sandblasting Abrasive.

FAQ

Q1: Ano ang ginagamit na ito?

It supports shot peening, descaling, and rust removal in industries such as automotive, aerospace, and railways. Bukod dito, it ensures reliable results in high-stress projects.

Q2: Maaari ba itong magamit muli?

Oo. Sa katunayan, this abrasive maintains strength after multiple blasting cycles. Samakatuwid, it reduces consumption and saves costs.

Q3: How does it compare to High Carbon Cut Wire Shot?

High manganese abrasive provides superior toughness and fatigue resistance. Bilang isang resulta, engineers choose it for parts exposed to extreme loads.