Steel Grit for Heavy-Duty Surface Preparation

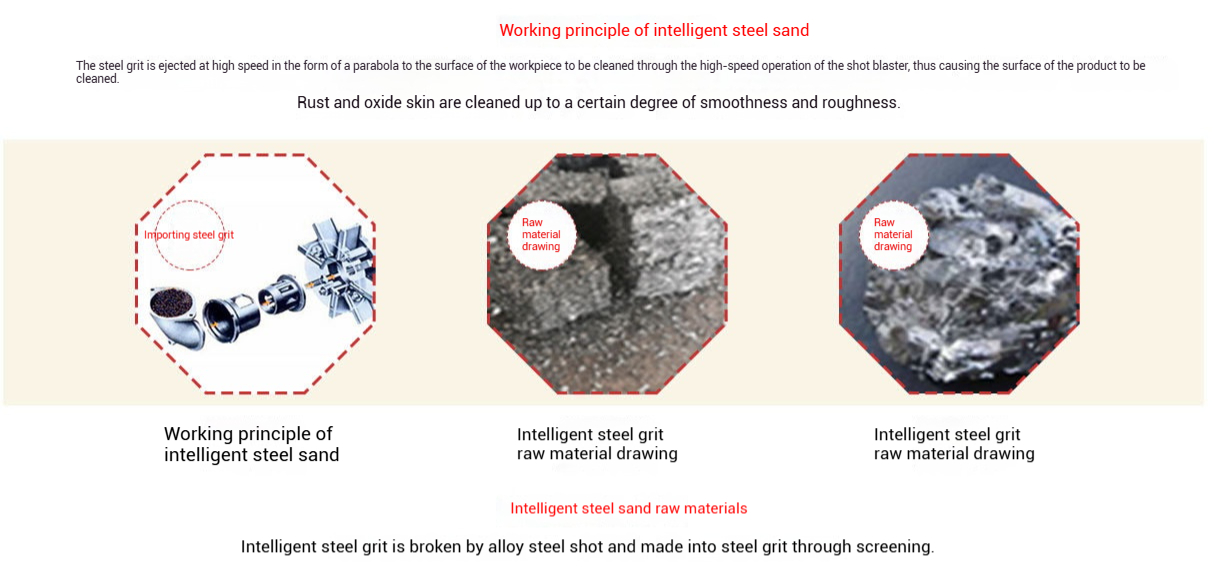

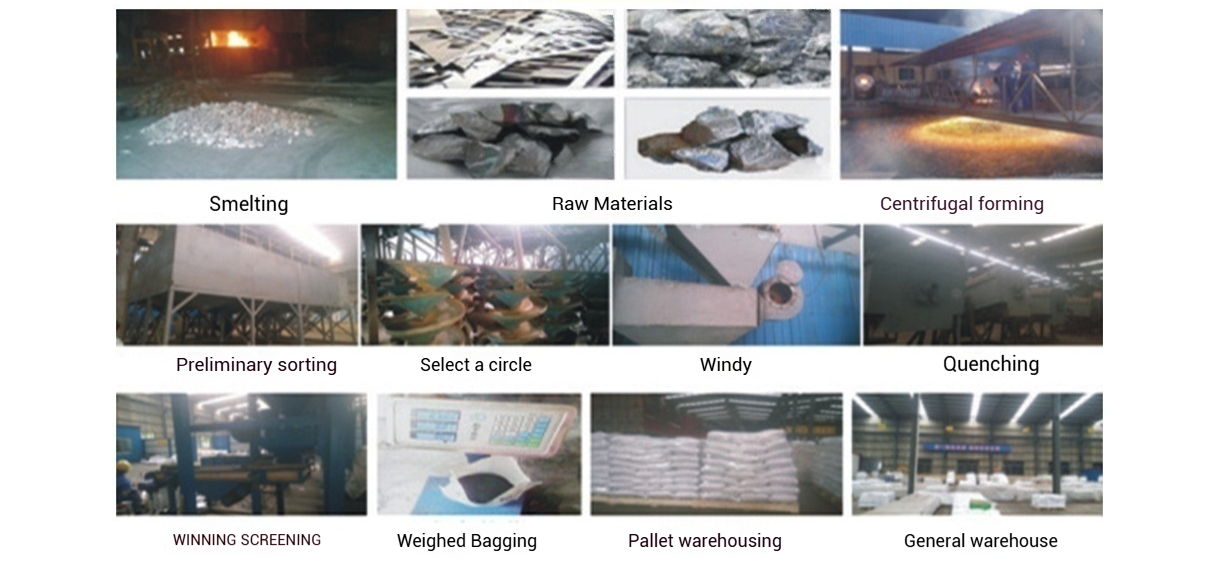

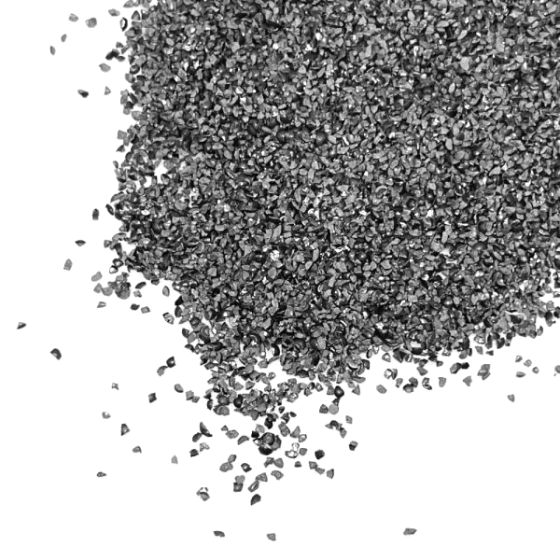

Manufacturers crush high-quality cast steel shot to produce Hạt mài mòn thép. Contractors widely use this angular metallic blasting media in heavy-duty surface preparation such as descaling, rust removal, and surface roughening. Kết quả là, it delivers aggressive impact force. Vì thế, it is ideal for cleaning ship hulls, structural steel, đường ống, and castings before coating or painting. Hơn thế nữa, its sharp edges and high hardness ensure consistent performance across industries.

Key Features of Steel Grit

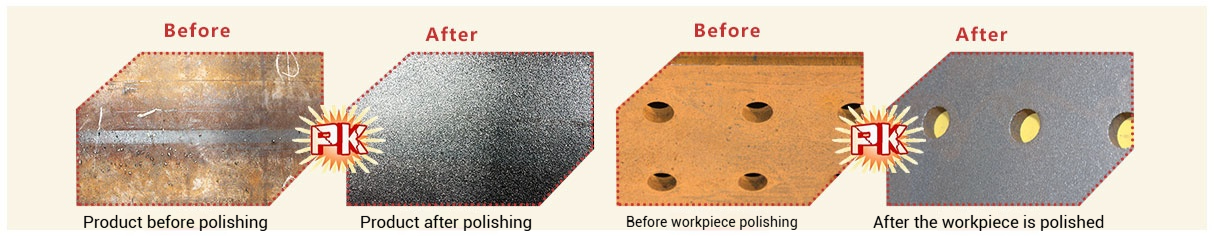

Angular Shape for Aggressive Cleaning: Sharp-edged particles provide superior rust and scale removal. Vì thế, blasting becomes faster and more efficient.

High Hardness & Toughness: Offers strong impact with excellent durability for repeated blasting cycles. Ngoài ra, this ensures a long service life in industrial blasting operations.

Long Reusability: Supports multiple recirculation cycles in closed-loop blasting systems. Hơn thế nữa, this reduces overall abrasive consumption and project costs.

Efficient Surface Profiling: Delivers consistent surface roughness that improves coating adhesion. Do đó, protective coatings last longer and resist harsh environments.

Wide Grit Size Range: Available in G10 to G120, or customized upon request. Kết quả là, different industries can select the size that best fits their blasting requirements.

Thông số kỹ thuật

| Vẻ bề ngoài: | polygonal prism |

| Particle Size (mm): | 0.3/0.5/0.7/1.0/1.2/1.5/1.7/2.0 |

Product Models

| G10 | G12 | G14 | G16 | G18 | G25 |

| G40 | G50 | G80 | G100 | G120 |

Tùy chọn đóng gói

We supply steel grit in:

25 Kg Túi dệt nhựa, thu nhỏ được bọc trên pallet xuất khẩu (1000 kg/pallet).

1000 Kg túi jumbo (dệt polypropylen với 4 Nâng vòng lặp).

Tóm lại, customers can always select a packaging method that suits their needs.

Industry Applications of Steel Grit

Steel grit abrasive is applied in:

Shipbuilding and Maintenance

Dầu, Khí, và các cơ sở hóa dầu

Monument and Building Facade Cleaning

Các dự án cơ sở hạ tầng (Cầu, Đường hầm)

Steel Fabrication and Construction Surface Preparation

👉 For international blasting standards, refer to ISO 11126 – Preparation of Steel Substrates.

👉 Đang tìm thêm lựa chọn? Ghé thăm của chúng tôi Tổng quan về chất mài mòn phun cát trang.

FAQ

Q1: What is steel grit used for?

Contractors use steel grit abrasive for blasting to remove rust, tỉ lệ, and old paint from steel structures, đường ống, and ship hulls. Kết quả là, it improves surface cleanliness and extends coating life.

Q2: Can steel grit be reused?

Đúng. In fact, steel grit abrasive remains highly durable and contractors recycle it many times. Vì thế, it is a cost-effective choice for large blasting projects.

Q3: What surface finish does steel grit provide?

Specifically, steel grit abrasive produces an angular surface profile that improves coating adhesion. Do đó, coatings bond better and last longer in harsh conditions.