工業噴砂用銅渣磨料

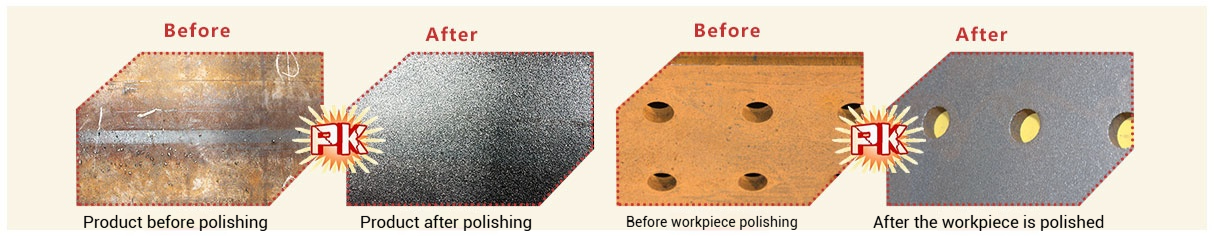

聯順銅渣磨料是專為造船廠設計的高性能噴砂介質, 石油管道, 橋樑, 和鋼結構. 而且, 它提供低游離二氧化矽含量, 快速切割動作, 和 一致的表面輪廓, 確保拋丸順利高效. 因此, 它具有出色的除鏽和塗層去除能力 儘管 提高保護塗層的附著力.

銅渣磨料的主要優點

高效除鏽: 後果 它們的棱角形狀, 這些顆粒可有效去除金屬表面的頑固鏽跡和氧化物.

低粉塵 & 環保: 含量小於 1% 游離二氧化矽, 這種磨料可提供更安全的操作並減少噴砂過程中空氣中的灰塵.

一致的表面光潔度: 而且, 它提供統一的錨定圖案,非常適合噴漆或塗層應用.

性價比高: 由於 它的耐用性, 它可以回收用於多個噴砂週期, 降低項目總成本.

- 多種應用: 此外, 廣泛應用於造船業, 石化廠, 管道, 鋼橋, 和基礎設施項目.

技術規格 & 網格尺寸

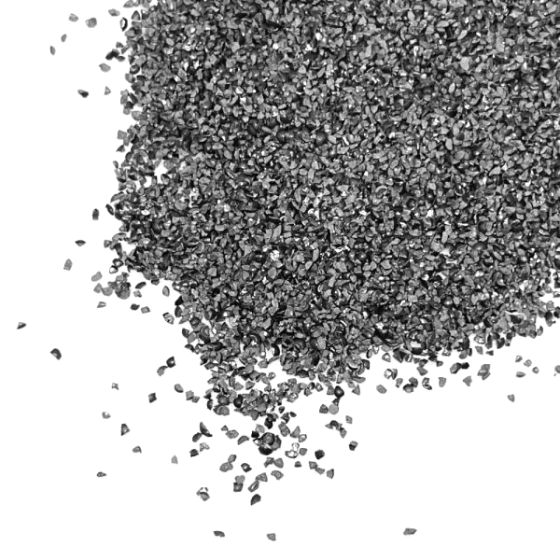

| 外貌: | 有角粒子; 深棕色或黑色 |

| 可用粒徑: | 5–8目/8–20目/10–20目/20–40目/40–80目 |

| 硬度: | ≥ 6.0 莫氏 |

| 游離二氧化矽含量 : | < 1% |

| 氯含量: | ≤0.0025% |

| 水提取物的電導率: | ≤25毫秒/米 |

包裝選項

- 25 公斤袋, 收縮包裹在出口托盤上 (全部的: 1000 每托盤公斤數).

- 1000 kg巨型袋 (編織聚丙烯, 和 4 舉起循環).

- 可根據要求提供定制包裝解決方案.

銅渣的工業應用

- 造船和修船 – 廣泛用於船體爆破, 壓載艙, 和海上平台達到 SA 2.5–3 表面清潔度.

- 油, 氣體, 和石化設施 – 清潔管道的理想選擇, 儲罐, 和塗裝前的煉油廠.

- 紀念碑和建築外牆修復 – 有效去除油漆, 污垢, 以及石頭或混凝土的風化層.

- 橋樑, 隧道, 和民用基礎設施 – 確保塗層附著力強,在惡劣環境下延長使用壽命.

- 鋼結構表面處理 – 為工業鋼框架上的保護塗層提供一致的錨固輪廓.

銅渣磨料常見問題及解答

銅渣磨料有什麼用途?

操作人員在噴砂時使用銅渣磨料去除鏽跡, 畫, 以及鋼鐵和混凝土表面的舊塗層. 他們在造船廠應用它, 管道, 橋樑, 和鋼結構達到 SA 2.5–3 表面清潔度標準. 了解更多關於 ISO 11126-3 礦物磨料標準.銅渣可以安全使用嗎?

是的. 我們的銅渣含量低於 1% 游離二氧化矽, 因此與傳統矽砂相比,它可以降低粉塵並確保更安全的噴砂. 我們仍然建議在操作期間使用適當的個人防護裝備.銅渣與石榴石相比如何?

銅渣切割速度更快,降低成本, 這使得它非常適合去除嚴重的鏽跡和水垢. 石榴石, 然而, 為需要更平滑輪廓的項目提供更精細的表面光潔度. 另一種選擇, 檢查我們的 鋼沙粒磨料.有哪些網格尺寸可供選擇?

我們提供網目尺寸如 5-8 的銅渣, 8–20, 10–20, 20–40, 和 40–80. 我們還可以根據特定項目需求生產定制尺寸.- 提供哪些包裝選項?

我們提供銅渣 25 千克袋收縮包裝在托盤上或在 1000 公斤噸袋,帶提升環. 我們還為批量訂單提供定制包裝.

此外, 請立即聯繫我們,獲取量身定制的噴砂解決方案, 完整的技術數據表, 或免費樣品報價. 而且, 我們的技術團隊可以為您提供磨料選擇方面的建議, 爆破參數, 和最佳的表面輪廓,以確保您的項目獲得最佳的塗層性能.

👉 尋找更多選擇? 訪問我們的 噴砂磨料概述 頁.